Process Upgrade Case | Efficiency Improvement from Single-Process Mold to Continuous Mold

background

The customer's original processSingle engineering modelEach processing step requires independent molds and multiple positioning. Although the quality can be maintained, the long production cycle, high labor input, and frequent process switching limit production capacity and cost increases.

Current situation assessment

- Manual handling and repositioning are required between multiple processes, increasing the risk of cumulative errors

- The production cycle is too long and large orders cannot be met immediately

- High reliance on manpower leads to increased management difficulty and costs

Technical Solutions

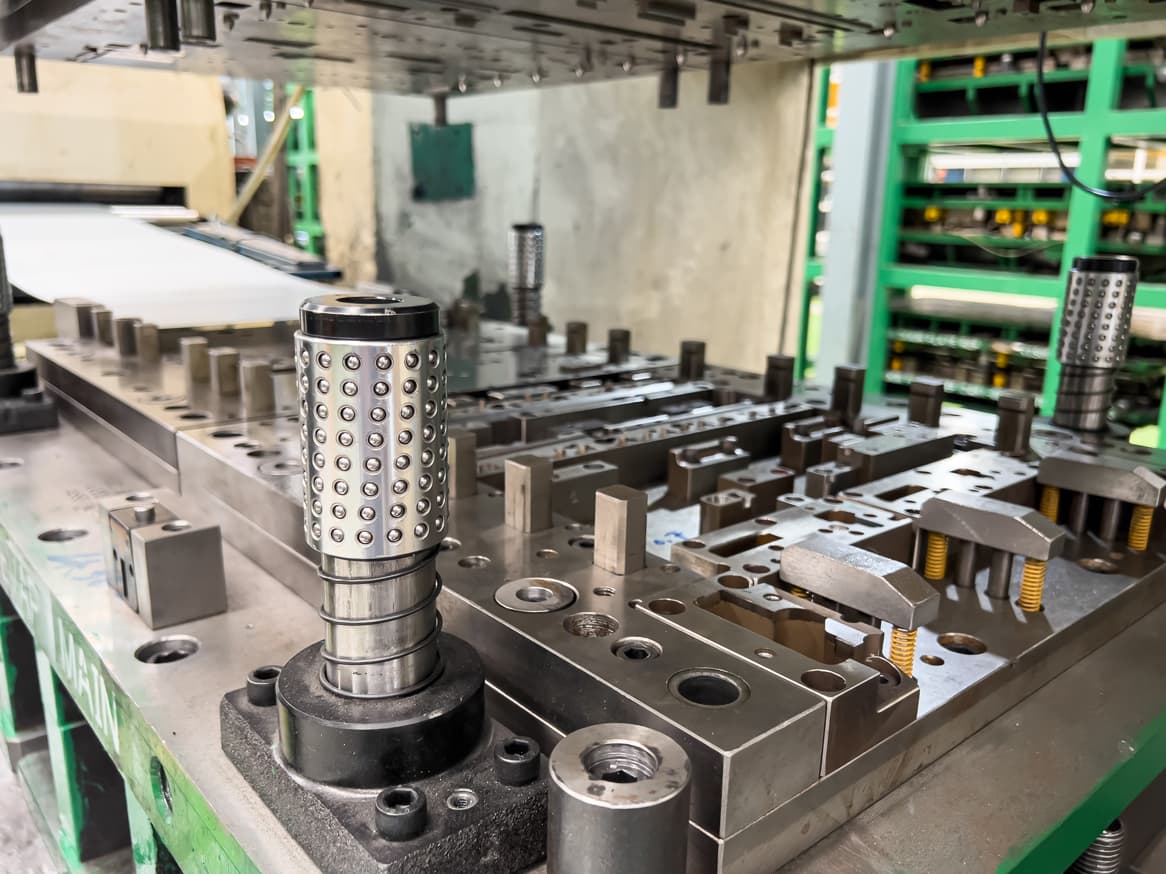

After joint evaluation by our engineering team and mold design department, we recommend the use of "progressive mold" for integrated production.

The core of this program is:The processing steps that were originally dispersed across multiple sets of single-process molds are now reconfigured within the same mold. Through an automatic feeder, the raw materials can complete all processing steps, including punching, bending, forming, and cutting, in sequence within a single mold stroke.

Project Execution

-

Process reorganization and mold structure design

The original five independent processes are integrated into a continuous die and completed with one feeding.

Designed a dedicated guide positioning mechanism to ensure accurate and consistent pitch -

Mold material and life optimization

Use high-toughness high-speed steel blade material to improve wear resistance

Titanium plating treatment is performed on key parts of the mold to extend the maintenance cycle -

Production equipment calibration and trial production verification

Through precision punching machine and automatic feeding system, stable and continuous operation is achieved

24-hour trial production, no dimensional drift or processing defects occurred

Benefits

- Capacity increase:Increased from 15 pieces per minute to 40 pieces per minute, with an increase in output efficiency of more than 100%

- Shortened process cycle:The production time for a single batch of 10,000 orders was reduced from 7 days to 8 hours

- Cost reduction:Processing costs reduced by 32% and manpower requirements reduced by 40%

- Stable quality:All machines are equipped with automatic inspection systems, with a full inspection pass rate of 99%. Quality control can also protect the molds.

in conclusion

This case demonstrates that converting single-process molds to progressive molds not only significantly improves production capacity and cost-effectiveness, but also enhances quality consistency and delivery stability. Our company will continue to create greater competitive advantages for our customers through process optimization and mold innovation.