Characteristics and advantages of continuous die stamping

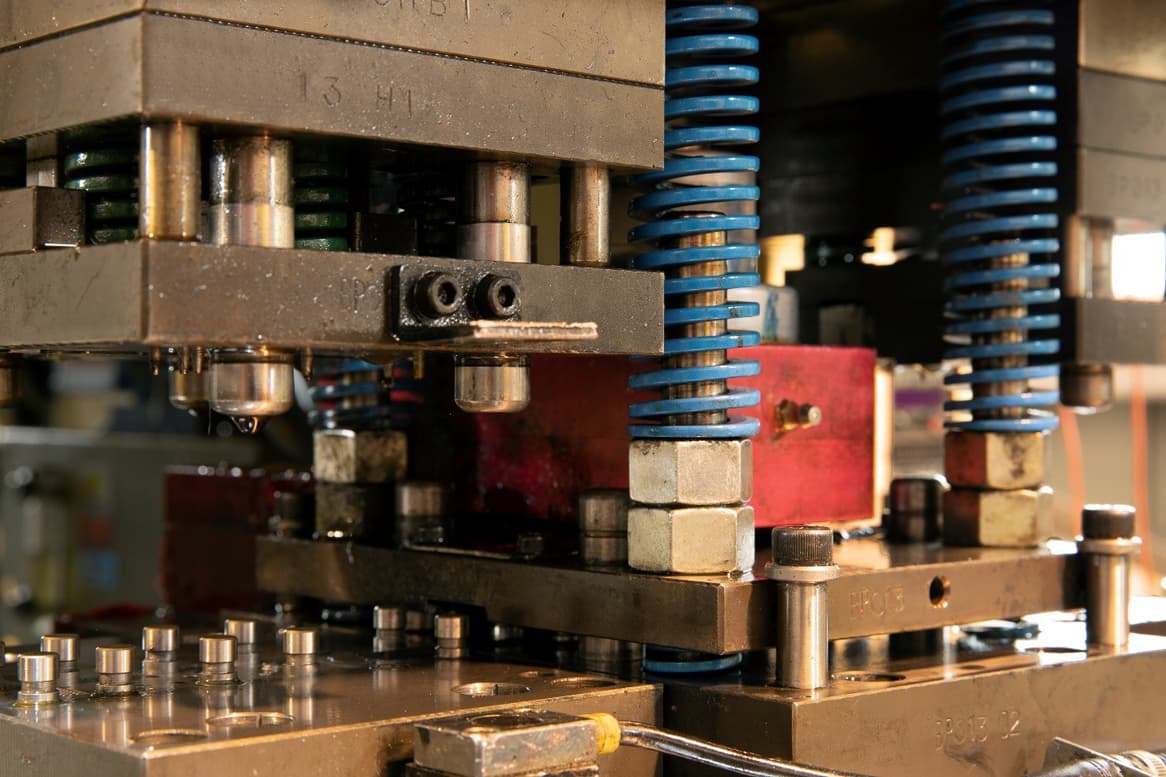

A continuous stamping die means that multiple stamping processes are performed "continuously" within the die, which may include blanking, punching, bending, forming and other stages.

The production process is that the whole material is fed into the mold in the form of a strip, and is pushed forward by the feeder at a fixed pitch. Each time the material is fed, the mold completes a process, and the finished product is cut from the strip at the last stage.

Its features and advantages include:

-

High performance:Combining multiple processes into one continuous mold eliminates the need for manual loading and unloading and frequent mold changes, allowing for uninterrupted production and improved production efficiency.

-

Product stability:Continuous molding through continuous strip processing ensures product precision at every stage of production. Repeated movements within the mold ensure consistency and product stability. Furthermore, the addition of advanced automated quality control sensors within the mold can extend mold life and maximize product yield.

-

Reduce human error:In the automated equipment for continuous production in the mold, only manual work is required to load the material and collect the finished product, which reduces product defects caused by manual operation and can greatly reduce labor costs.

-

Reduce costs:Progressive molds are usually more suitable for products with stable demand and large-scale production. Efficient production can not only reduce time costs but also evenly distribute and reduce the costs of machinery, parts, and molds.

Common considerations for opening continuous molds:

-

Pitch calculation:The distance between each stage must be precisely designed to ensure accurate material feeding and to ensure that material hardness and the design of each stage do not affect each other. If the pitch is too small, it may cause material deformation, mold failure, and cracking. If it is too large, it will result in material waste and mold space wasted.

-

The order of processing levels is arranged as follows:The order of the finished product's processing steps must be considered in advance, such as punching first and then drawing the tube, drawing the material first and then forming it, or forming it first and then punching it to ensure the holes don't deform. Sometimes, this is done to avoid practical issues such as material elasticity and hardness by reserving checkpoints in advance for subsequent adjustments.

-

Guidance and positioning system:The pilot pins should ensure that each template is positioned correctly to ensure stable feeding and chip removal.

-

Mold strength and chip removal design:It is necessary to ensure that the materials of the master mold and the punch are of sufficient strength and have effective chip holes for the removal and dropping of chips. In addition, consumable parts such as the punch and the master mold block should be designed to be easily replaced.

-

Module design:The mold is equipped with monitoring devices, which automatically detect during production to ensure production stability and protect the life of the mold. Monitoring devices include: infrared transmission sensors, touch sensors, etc.