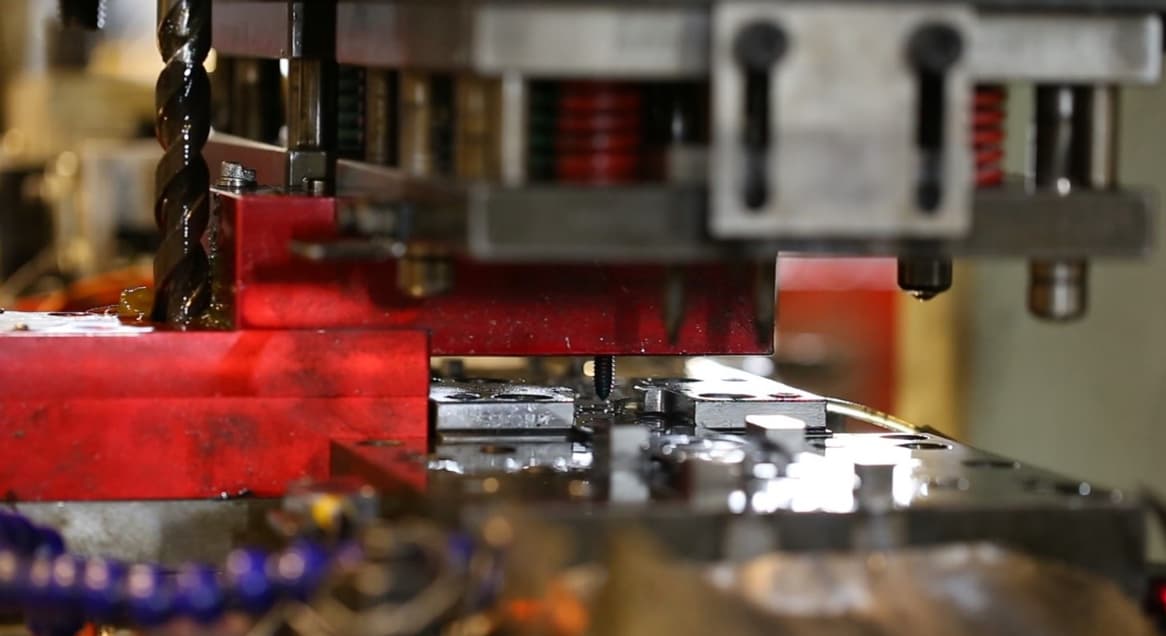

What is in-mold tapping?

As the name suggests, the tapping process is integrated into the stamping die. Once stamping is complete, the tapping is also completed. Unlike traditional manual tapping, in-die tapping allows for more labor-saving automation and more stable quality.

Advantages of in-mold tapping:

-

Improve production efficiency - reduce the time of manual unloading and loading of finished products, and directly complete the stamping and tapping in one step.

-

Reduce human errors - reduce the NG rate of missed tapping or incomplete tapping due to improper manual operation.

-

Cost savings - reduce labor costs and equipment costs of tapping machines.

-

Improve thread accuracy: Tapping is completed directly in the mold to ensure the depth, accuracy and consistency of the tapped threads, avoiding positioning errors caused by subsequent processing on the machine again.