Stamping structure of craft hardware decorative parts|Aesthetic core

"Stamping as the skeleton, craftsmanship as the soul" - the hero behind contemporary craft door handles and decorative parts

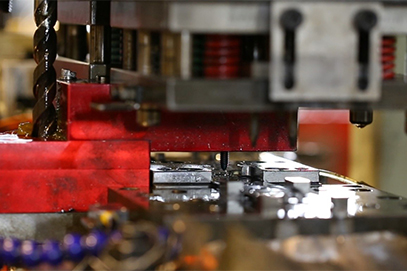

Traditionally, stamping door handles with intricate carvings or rich, textured finishes were nearly impossible. However, with the advancement of manufacturing technology, stamping has gradually become a key player in modern high-end door handles and door and window trims. It serves as both a structural foundation and a finishing touch, becoming an invisible yet indispensable contributor.

1. Why are craft door handles rarely made of stamping?

Handicraft door handles emphasize three-dimensional carvings, a solid feel, and artistic shapes. These characteristics impose natural limitations on stamping:

- Limited styling:Stamping forms a two-dimensional sheet into a three-dimensional shell shape, making it difficult to create deep carvings.

- Limited material mobility:Excessively complex or deep stretching is prone to cracking.

- Structural characteristics:Most stamped parts are hollow and thin shells, which cannot provide a heavy grip feeling.

Therefore, traditional craft door handle cores are usually made by casting, forging or CNC processing.

2. The Fusion Role of Stamping

Despite this, stamping still plays an "integration" role in modern craft door handles:

- Basic components:For example, the base (Rosette) and internal fixed structural parts can be stamped with high efficiency and consistency.

- Appearance extension:Through precision molds and post-processing, stamping can even produceFlowers, leaves, vines, branches, geometric patterns, embossed embossing, decorative coats of arms, borders, small three-dimensional piecesThese artistic elements, which originally relied on casting, can now be efficiently presented by stamping.

3. When stamping itself becomes a "craft"

In minimalist or modern design, craftsmanship no longer refers only to complicated decoration, but a combination of precision and texture.

- Material upgrade:Brass, stainless steel thick plate.

- Exquisite surface treatment:Hand polished and PVD coated.

- Design presentation:Contrast of smooth lines, mirror and brushed surfaces.

This allows stamping parts, even hollow structures, to exhibit artistic effects comparable to castings.

in conclusion

The relationship between stamping and craft door handles, door and window decorations is moving from "unrealizable" to "integrated symbiosis":

- Traditional level:Stamping cannot independently produce heavy and complex craft bodies.

- Modern applications:Stamping is the optimal solution for basic structural parts.

- Decoration extension:Stamping can be used to efficiently produce artistic pieces such as flowers, leaves, and coats of arms.

- Design level:Stamping itself can also become a modern craftsmanship expression method.

Stamping is not just a function; it also carries structure, efficiency and design language, and is an indispensable cornerstone of contemporary craft hardware.