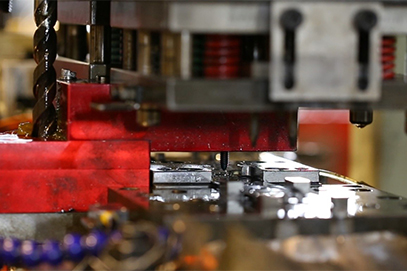

Stamping application range

The application range of stamping is small, ranging from daily life to everything. Is there anything we can't imagine?

Stamping technology is widely used in modern industry and life. Here are some of our unexpected application areas:

-

Medical devices:Many precision medical devices such as surgical tools, dental equipment, and implant parts are manufactured by stamping, a process that requires stringent precision and sterility requirements.

-

Aerospace:The aircraft's metal shell, fixed parts, and even some complex internal structures are manufactured using stamping technology to ensure their lightweight and strength, and 100% full inspection quality. When it comes to flight safety, only 100% is allowed, not 99%.

-

3C electronic products:Stamping technology is widely used in metal casings, connectors, heat sinks, etc. in smartphones, laptops and other electronic products.

-

New energy equipment:The casings and electrode sheets of electric vehicle batteries, as well as the frames of solar panels, also rely on stamping to achieve mass production and consistency.

-

Appliance structure:Metal brackets, fixings and internal structures in household appliances such as washing machines, refrigerators and microwave ovens.

-

Art and Decoration:Stamping is not limited to functional applications, but is also used to create metal decorations with exquisite patterns, such as high-end furniture accessories, art ornaments, etc.

-

Sporting Goods:Bicycles, fishing accessories, mountaineering equipment, ski components, and fitness equipment. By utilizing high-precision technology and diverse mold design capabilities, stamping is widely used in various fields.